IXL Co., Ltd. is an exclusive manufacturer and distributor of Polyphen® in Thailand, Laos, Cambodia, Vietnam, Burma and Malaysia. Polyphen® is a fire resistant insulation foam. IXL FR panel with Polyphen® core is therefore also highly fire-resistant and is certified by FM Approvals Class: 4880, 4882.

IXL FR Panel with Polyphen® Core – A Fire Resistant insulation foam

Structural Insulated Panels

IXL Co., Ltd. and Polyphen® signed License Agreement to be the exclusive manufacturer and distributor of Polyphen® in Thailand, Laos, Cambodia, Vietnam, Burma and Malaysia

Polyphen® – A Fire Resistant insulation foam

“Fire protection” must be accounted in the design to:

“Mitigate” potential loss from fire;

“Reduce or limit” damages from fire;

“Increase” time to escape

“Increase” fire control time

Polyphen® has been proven to pass FM Standard 4880 Fire Test, not only in Australia, New Zealand, South Africa but also in Thailand. IXL FR Panel with Polyphen® Core being produced by IXL Co., Ltd. already passed FM Standard 4880 and 4882 Fire Test.

Approval Standard FM 4880

Class 1 Fire rating of building panels or interior finish materials

Room Corner Test

Room Corner Testing at 12th minute, limited flame and flame spread

Damage of the room corner after the end of 15min fire testing

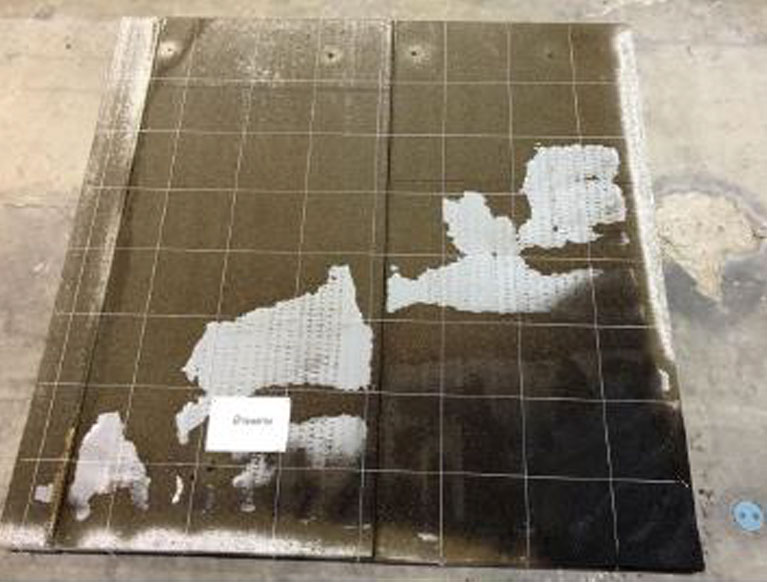

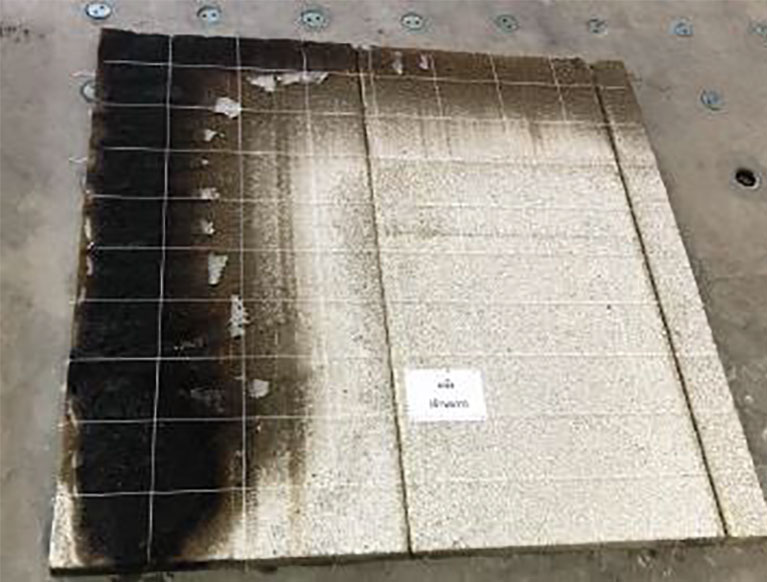

Condition of IXL FR panel with Polyphen® core with steel removed to check for damage

Images of FM Approvals Class: 4880, Room Corner Test of IXL FR panel with Polyphen® core produced in Thailand by IXL Co., Ltd.

Approval Standard FM 4882

Class 1 Interior wall and ceiling materials or systems for smoke sensitive occupancies

High Parallel Panel Test

Testing in progress for 4 minutes

Testing in progress for 8 minutes

Testing in progress for 10 minutes

Images of FM Approvals Class: 4882, High Parallel Test of IXL FR panel with Polyphen® core produced in Thailand by IXL Co., Ltd.

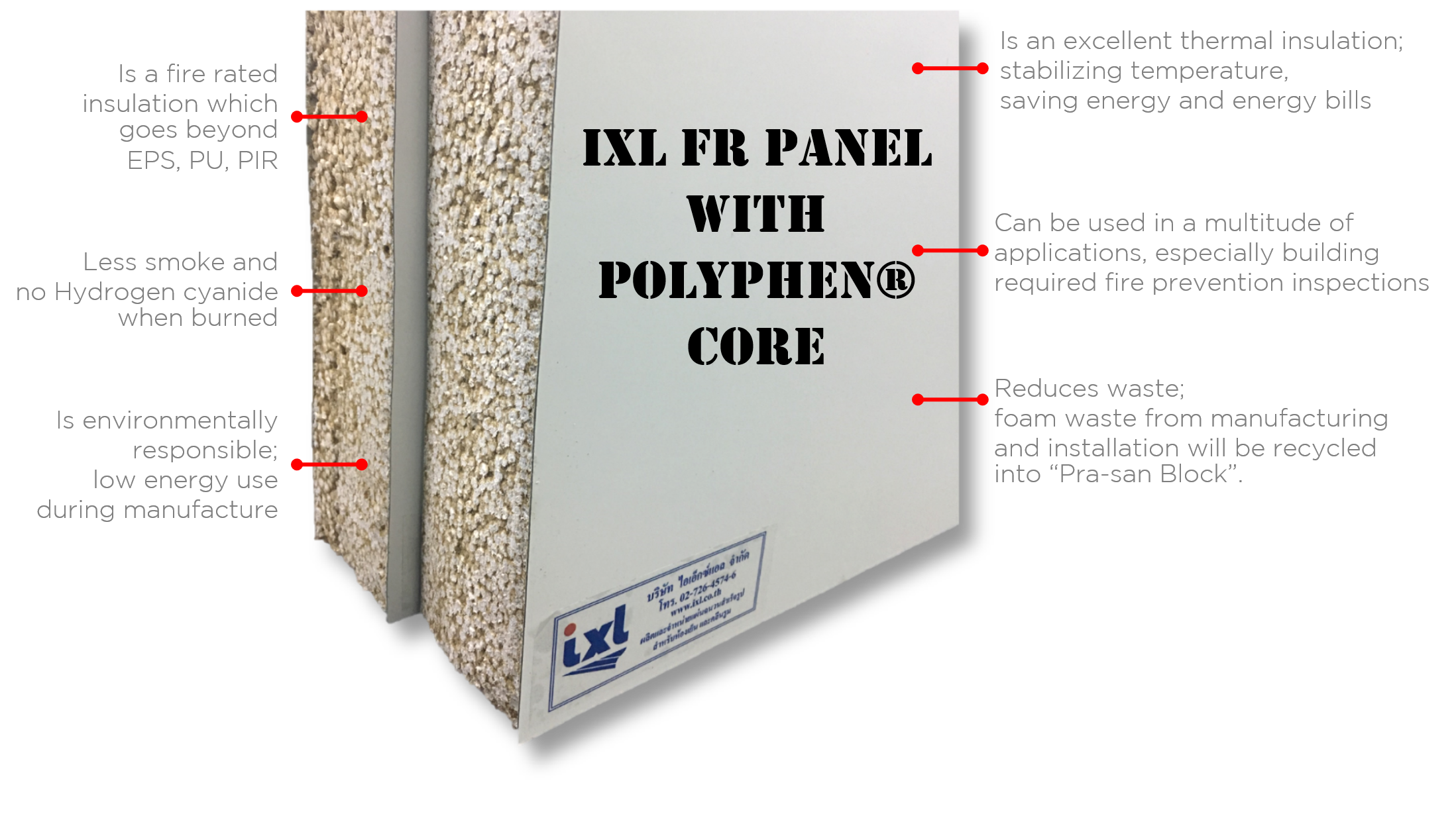

IXL FR Panel with Polyphen® the Best of Hybrid Foam

Polyphen® – A Fire Resistant insulation foam

A novel fire resistant insulation foam

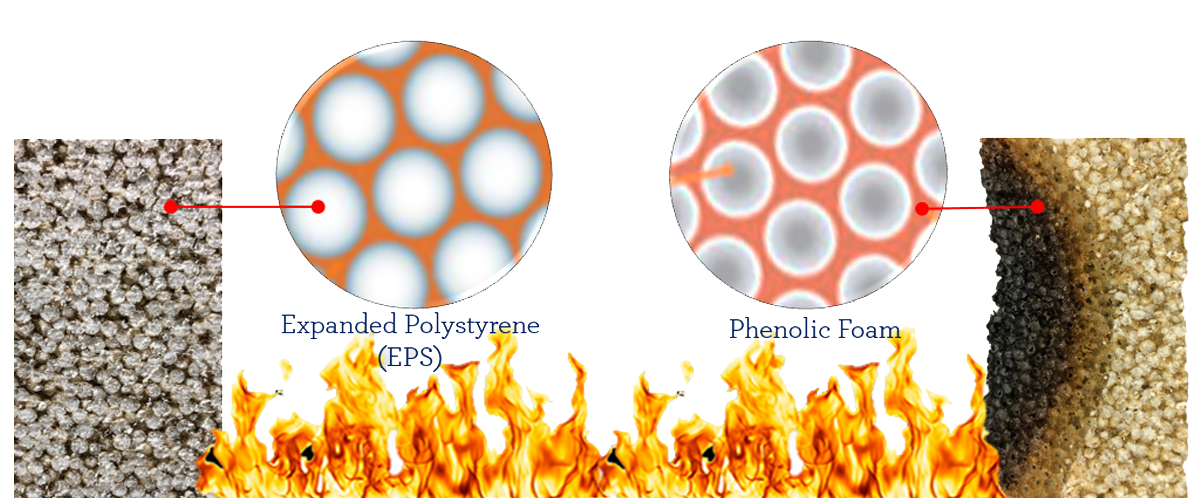

How Polyphen® works

In a fire situation, the EPS will decompose and evaporate. When this occurs, the Phenolic foam is left in a honeycomb shape and acts as a fire buffer.

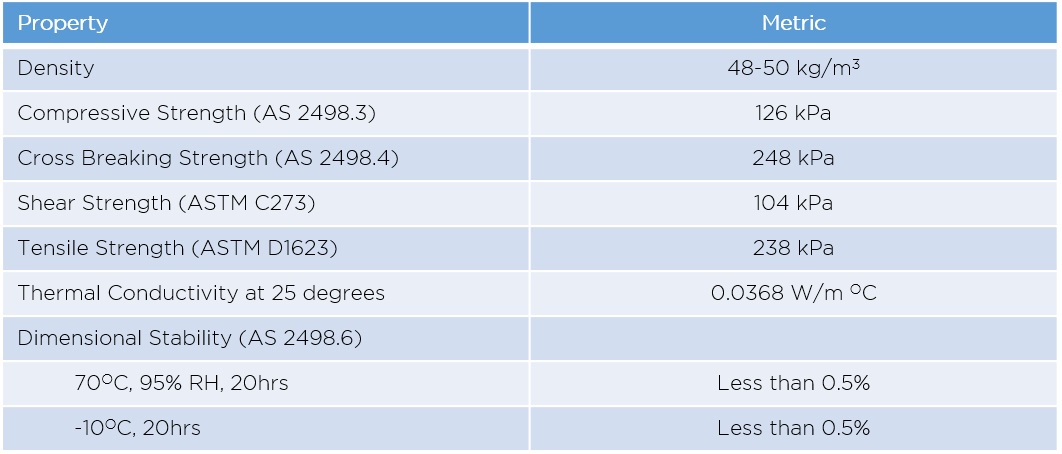

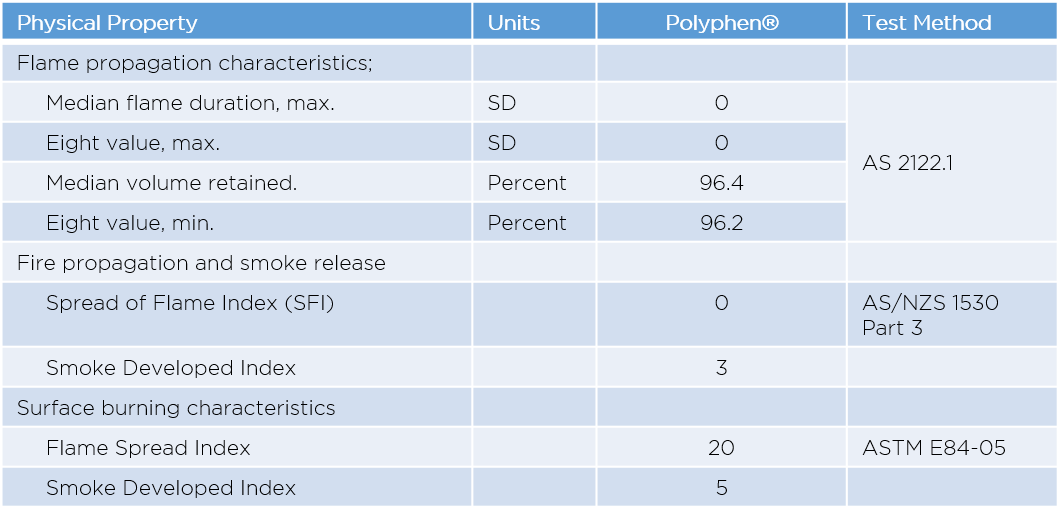

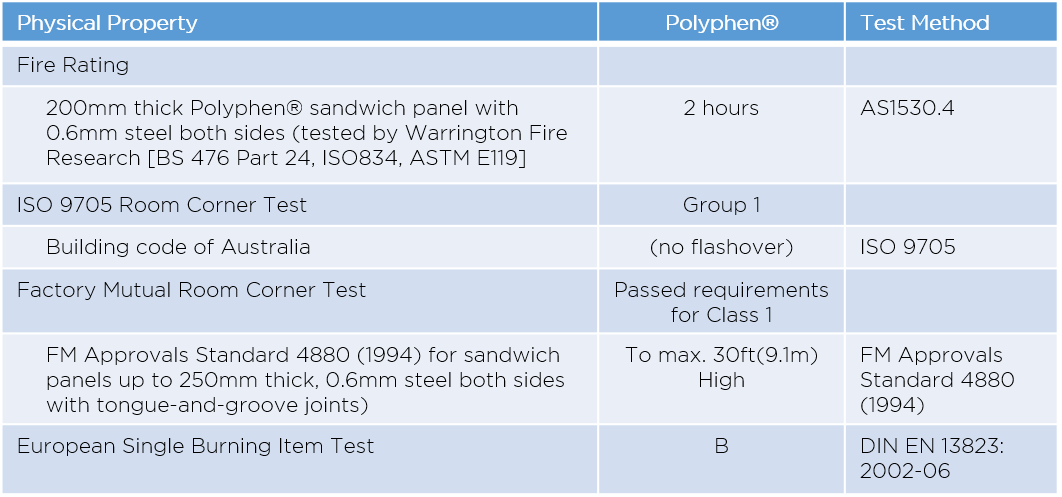

Polyphen® Technical Information

The following test results were obtained for a nominal 50kg/m3 foam manufactured in both Australia and New Zealand. Polyphen® manufactured in Thailand is identical to the product tested in Australia and New Zealand.

Remark: The physical properties listed above vary with the density of Polyphen®

Polyphen® has sound absorbing properties

- Polyphen® can be made with similar noise reduction properties as Acoustic Polyurethane foam.

- A Noise Reduction Coefficient NRC=0.45 (250-2000 Hz) has been recorded for 30mm thickness. That means, this product can be used for acoustic applications e.g. ceiling tiles, wall linings and office partitions, to reduce disturbing echoes.

Biological Resistance

- Mould – does not promote mould growth

- Vermin – offers no food value to insects or rodents

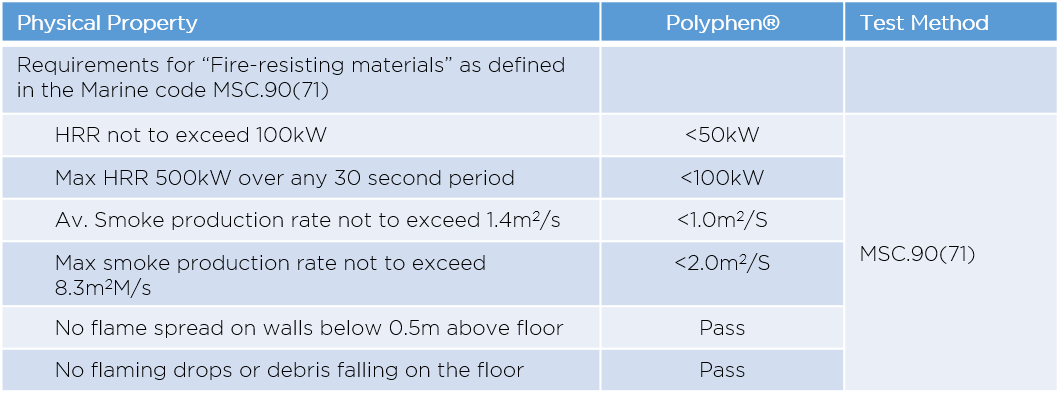

Polyphen® Fire Resistance Properties

The following test results were obtained for a foam manufactured in both Australia and New Zealand. Polyphen® manufactured in Thailand is identical to the product tested in Australia and New Zealand.

UBC 26-3: Room fire test standard for interior of foam plastic systems

Results of IXL FR Panel with Polyphen® UBC 26-3 test with 15 min fire exposure

- No flare flame-out through the front door of the testing room and no flashover

- Produced small amount of smoke

- No burn at the edge panel and the outer edge of the test room area

IXL FR Panel with Polyphen® produced by IXL Co., Ltd. is likely to pass the UBC 26-3 test.

Tested and reported by

Center for Engineering Service,

Faculty of Engineering,

Chulalongkorn University

IXL FR Panel with Polyphen®

Fire testing in progress

at 7 minutes

Fire testing in progress

at 15 minutes

Room damage after test

Damage to corner specimens

Damage to wall and ceiling

Ceiling damage in region of direct flame contact

Edge panel damage in region of direct flame contact

Wall damage in region of direct flame contact

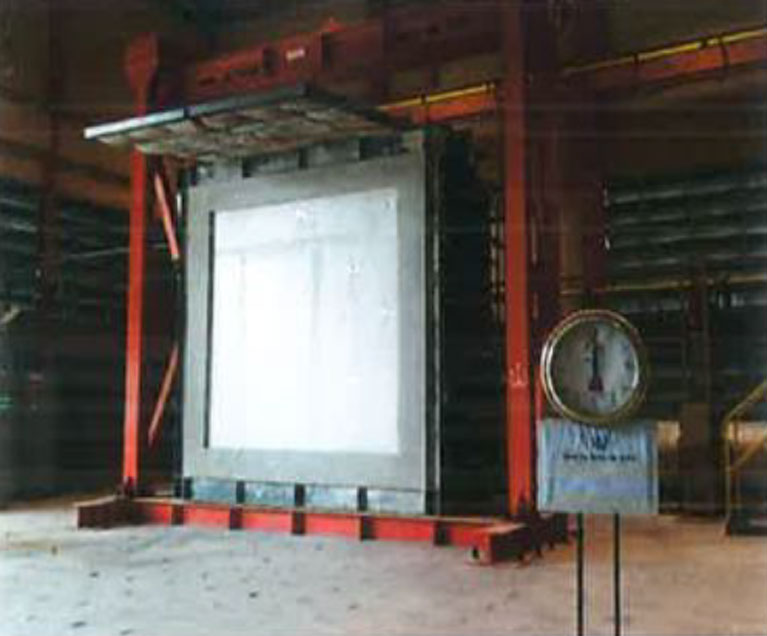

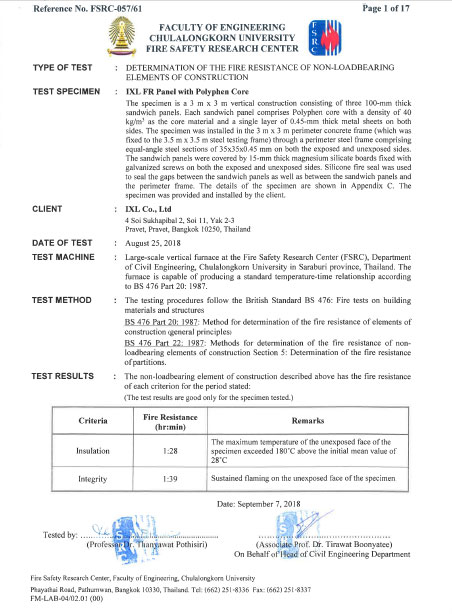

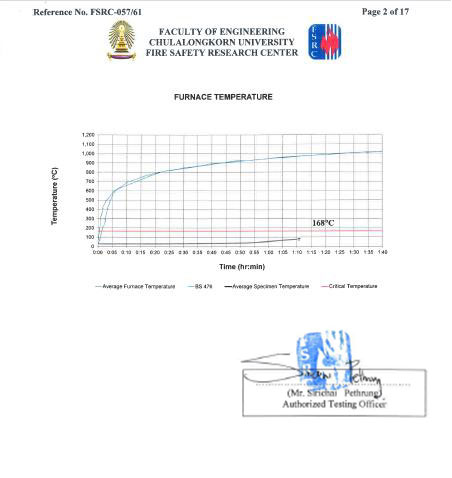

British Standard BS 476: Fire test on building materials and structures

IXL FR Panel

with Polyphen®

Fire testing in

progress at 60 minutes

Fire testing in

progress at 99 minutes

Damage

after the test

IXL FR Panel with Polyphen® The Best Hybrid Foam

Polyphen® – A Fire Resistant insulation foam