Cold room (Cold Storage) is a room that keeps the temperature low. The temperature of the cold room is varied, depending on usage. Generally, the temperature is -18 degrees Celsius. Cold room is mostly used for storage of perishable food such as seafood, meat, vegetables, fruits etc.

Whether to build what type of cold room (cold storage), it depends on the type of food such as chilled vegetables and fruits, frozen meat and meat products, chilled milk or dairy products. They are stored in cold storage at different temperatures.

For example, chilling vegetables and fruits keeps fruits and vegetables at a low temperature but higher than the freezing point. Chilling injury occurs at temperatures well above freezing point. Symptoms include surface lesions/pitting, internal discoloration, water soaking of the tissue, failure to ripen normally, etc.

Degrees of coldness in food preservation

Freezing at temperatures above freezing point

Refrigeration is usually at a temperature of 0-5 degrees Celsius. Cooling is used to preserve the growth of the micro-organisms contained in the food, not to destroy the micro-organisms. Low temperatures slow down microbial metabolism, which accordingly slows food decay.

Freezing at temperatures below freezing point

Freezing in a freezer is a long-term preservation at temperatures below 0 degree Celsius. If properly treated food at the right temperature, freezing will effectively preserve flavor, color and nutritional value. However, freezing can moderately preserve food texture.

2 freezing methods

- Slow Freezing: It takes about 3 to 7 hours to complete. Products are stored at -15 degrees Celsius or lower.

- Quick Freezing: It takes about 30 minutes or less to complete. To make the whole product frozen, products are stored at -18 degrees Celsius or lower. It is usually kept at -40 degrees Celsius to -18 degrees Celsius.

Types of cold rooms

Air Blast Chill Room

Food is usually stored at 2-10 degrees Celsius

Freezer Room

Food is usually stored at -5 degrees Celsius to -25 degrees Celsius

Cold Storage Room

Food is usually stored at -25 degrees Celsius. Note that this cold storage is suitable for storing already frozen products.

Air Blast Freezer Room

Food is usually stored at -35 degrees Celsius. It takes about 4 to 5 hours to freeze the products.

Anti Room

Food is usually stored at -5 degrees Celsius to 10 degrees Celsius. This cool room is suitable for stocking or distributing.

Face Profile Option For Cold Room

For a cold room (or cold storage), it is recommended to use galvanized steel (CB) for rust prevention, coated with 3-layer Modified Polyester (Food Grade). This complies with USDA standards and regulations.

- BlueScope SD ZM180 Antibacterial Steel: Zinc Coat 180 g/m2, 0.45-0.60mm total coated thickness (TCT)

- BlueScope SD ZM120 Steel: Zinc Coat 120 g/m2, 0.45mm total coated thickness (TCT)

All panel joints and corner angles of cold rooms shall be sealed with gun applied butyl mastic (non-hardening sealant)

(See details)

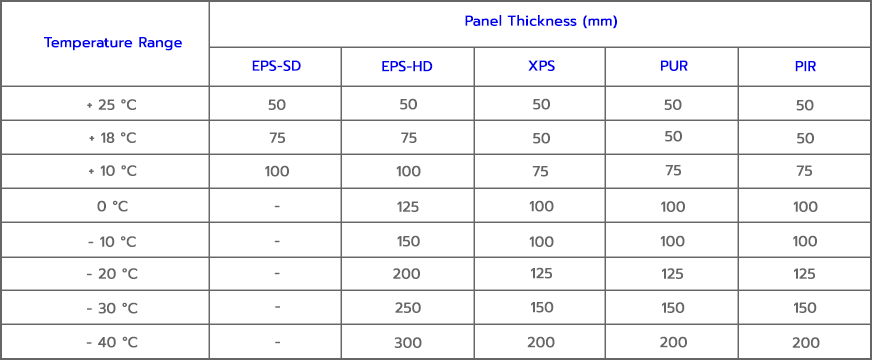

Insulation Option For Cold Room

To choose insulation options and its thickness depending on the temperature required in the cold room (cold storage)

EPS (Expanded Polystyrene) is generally used in cold room (cold storage) panel applications due to its insulation properties and high strength to weight ratio. Two grades of EPS are utilised in IXL Insulated Panels; P – Grade (standard) and F – Grade (Self Extinguish).

(See details)

XPS (Extruded Polystyrene or Styrofoam) is used in applications where a higher strength to weight ratio is required. Styrofoam offers greater insulation properties as well as higher resistance to water absorption and water vapour permeability and reducing the risk of ice formation in cold room or cold storage applications.

(See details)

PUR (Polyurethane) is made from fully cured foam slabs thereby ensuring they are flat and not subject to further shrinkage when cut. Besides being a high insulating material, it is also CFC free ensuring and Ozone Depletion Potential (ODP) of zero. See details.

(See details)

PIR (Polyisocyanurate) has similar properties to PUR. Even though PIR is not non – combustible, it does not burn in the same way as other foams such as EPS and PUR. When subject to fire, PIR forms a carbonaceous layer which retards further flame spread and penetration.

(See details)

Advantages of IXL Panels

- IXL panels can be cleaned easily with water or water with soap dissolved or water with detergent dissolved. Then rinse with clean water.

- IXL panels can retard further flame spread and penetration.

- IXL panels can relieve heat flowing into building, save electricity costs.

- IXL panels are vapour seal, low water absorption.

- IXL panels effectively maintain the temperature to the desired level.

A complete check prior to lowering the temperature of the cold room/ cold storage to the required operating temperature to ensure that the insulated room has been constructed in accordance with the Specifications and the approved construction drawing. The following should be checked as appropriate.

(See details)

Cold Room Accessories

Pressure Relief Ports are designed for installation in cold room/ cold storage to relieve pressure on the insulated panels (wall and ceiling). Pressure on the wall and ceiling is caused by temperature change in the room. The effect of this is contraction or expansion of air in the room during temperature pull down and temperature rise during defrost.

(See details)

In a cold room/ cold storage without Pressure Relief Valve (PRV), the pressure difference between the inside and outside of the room during initial temperature pull down could cause the room to cave in. Much the same as a vacuum being drawn on a 20-litre fuel tin.

(See details)

In a cold room/ cold storage without floor heater, the hazardous frost will be formed on the driveway, which endangers loading and unloading operations, the frost on the door lip seals require to use force to open the doors.

(See details)

Reasons for installing floor heater and heating mats laying in the concrete door area of cold room/ cold storage.

(See details)

The majority of the aluminium supplied by IXL Co., Ltd. has its natural corrosion resistance further enhanced by additional surface protection. This finished produces a surface that is both attractive in appearance and low in maintenance

(See details)

All 3 rails (3500 – 4400 – 7500) share the same patent. The mobile part of each system is located inside the track which also acts as a cover and simplifies the maintenance. Products are in accordance to European Directives and Standards.

(See details)

Recommendations on Cold Room Doors Maintenance

(See details)

IXL standard PVC strip curtains have been proven to maintain the temperature in a room, instant energy savings. PVC strip curtains can be seen through, walk pass through and drive through. PVC strip curtains commonly used in cold rooms are: Standard curtain, Super Polar curtain and Double Ribbed Transparent curtain.

(See details)